PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Q195 galvanized coils can also be roughly processed as needed (such as flattening, stripping, etc.), and can also be delivered to the factory, showing its flexibility and convenience in practical applications.

LEARN MORE

The galvanizing treatment of DC01 galvanized coil material is an economical and effective rust prevention method, and about half of the world's zinc production is used for this process. Galvanized steel sheet refers to a steel sheet with a layer of zinc on the surface. This treatment can significantly improve the corrosion resistance of the steel sheet and extend its service life. DC01 galvanized steel sheet is widely used in fields that require rust and corrosion resistance, such as construction, home appliances, automobile manufacturing, etc.

LEARN MORE

Excellent welding performance: In addition to processing performance, DX52D galvanized coil material also has good welding performance, which can facilitate various welding operations. This feature is particularly important for projects that need to connect different parts or build structures, because it can ensure the strength and reliability of the welded joints.

LEARN MORE

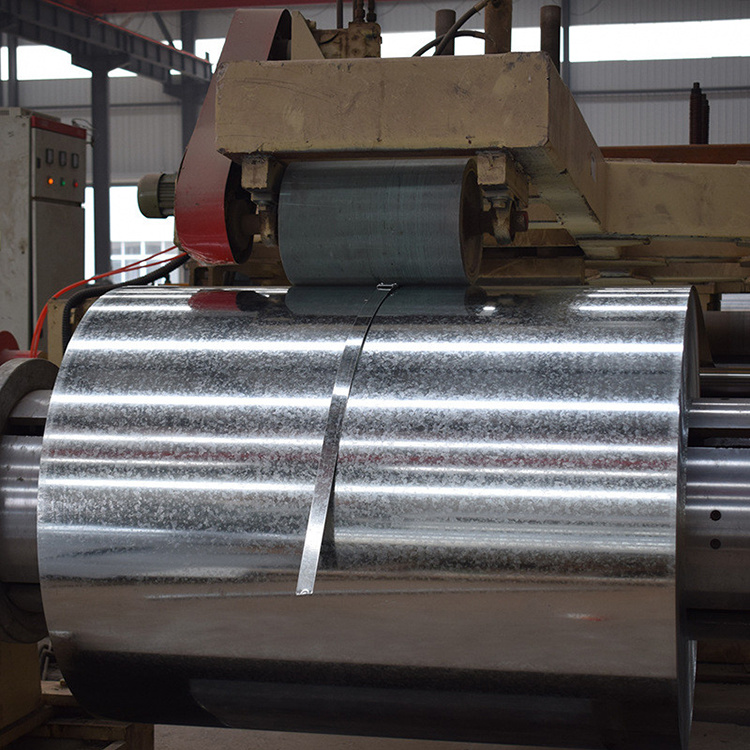

This material can be coated with a layer of metallic zinc on the surface of the steel plate to prevent the surface of the steel plate from corrosion, thereby extending its service life. Galvanizing is an economical and effective anti-corrosion method, and about half of the world's zinc production is used for this process.

LEARN MORE

G550 galvanized coil has a high surface finish and can be directly painted and processed. It is widely used in the manufacture of home appliances and construction industries. At the same time, galvanized coil also has good welding performance and can be welded with other metal materials, making it more convenient and quick in the manufacturing process.

LEARN MORE

The production method of Q235 galvanized coil is mainly hot rolling, and its surface is galvanized, which is an economical and effective rust prevention method. The presence of the galvanized layer can significantly improve the corrosion resistance of the steel and extend its service life.

LEARN MORE

In terms of application, ST12 galvanized coil material is widely used in many industries due to its excellent physical and chemical properties. Due to its good deep drawing performance, coating processability and electrical silicon steel sheet use, ST12 galvanized coil is mainly used in automobiles, printed iron drums, construction, building materials, bicycles and other industries. In addition, it is also the preferred material for the production of organic coated steel sheets.

LEARN MORE

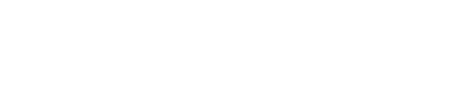

The production process of galvanized coils is mainly to coat the surface of the steel coil with a layer of zinc to achieve anti-corrosion protection. This coating can be formed in different ways, including normal zinc spangle coating, small zinc spangle coating, zinc spangle-free coating, zinc-iron alloy coating, differential thickness coating and skin-finishing, etc., to meet different usage needs and performance requirements.

LEARN MORE