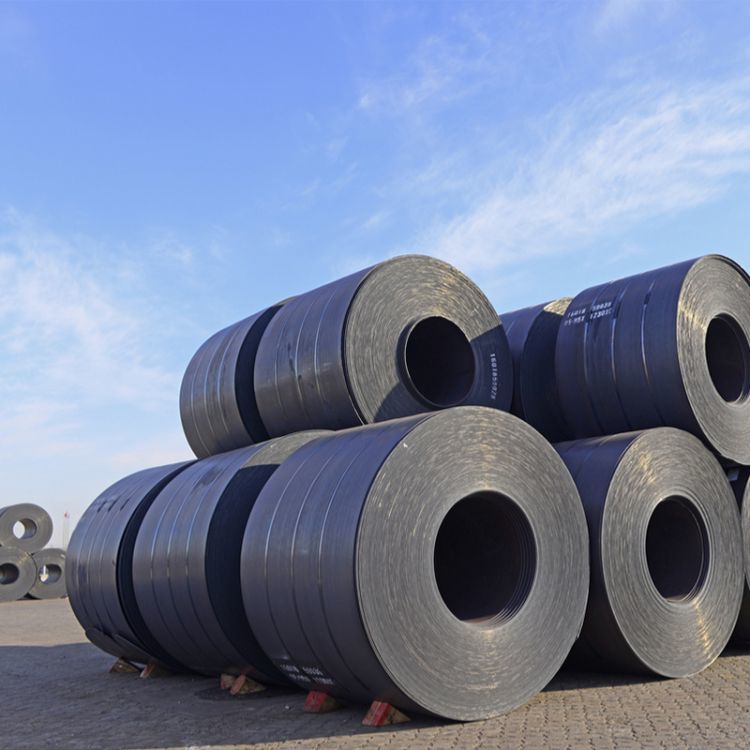

ST37 Carbon steel coil

Classification :

Keywords:

Carbon steel coil

PRODUCT DETAILS

ST37 Carbon Steel Coil Description

ST37 steel coils are suitable for flange beams, steel bars, steel strips, steel plates, wide flat steel, seamless steel pipes and welded steel pipes, square and rectangular hollow profiles. According to standards, ST37 steel plates are used for welding, riveting and threaded structural parts. Except for stress relief heat treatment and normalizing, it is not used for heat treatment.

Product Parameters

| Product Name | ST37 Carbon Steel Coil |

| Production Process | Hot Rolling, Cold Rolling |

| Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

| Width | 45mm-2200mm |

| Length | Custom Size |

| Thickness | Hot Rolling: 2.75mm-100mm Cold Rolling: 0.2mm-3mm |

| Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

| Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

| Brand | C | P | S | N | ||||

| ≤ 16mm | 16-32mm | 32-40mm | 40-63mm | 63-100mm | ||||

| St37-2 | 0.17 | 0.20 | 0.20 | 0.20 | 0.20 | 0.050 | 0.050 | 0.009 |

| USt37-2 | 0.17 | 0.20 | 0.20 | 0.20 | 0.20 | 0.050 | 0.050 | 0.007 |

| RSt37-2 | 0.17 | 0.17 | 0.17 | 0.20 | 0.20 | 0.050 | 0.050 | 0.009 |

| St37-3 | 0.17 | 0.17 | 0.17 | 0.17 | 0.17 | 0.040 | 0.040 | - |

| St52-3 | 0.204 | 0.204 | 0.22 | 0.22 | 0.22 | 0.040 | 0.040 | - |

Mechanical Properties

| Brand | Tensile Strength | Yield Strength | |||||

| <3mm | 3-100mm | ≤ 16mm | 16-40mm | 40-63mm | 63-80mm | 80-100mm | |

| St37-2 | 360-510 | 340-470 | 235 | 225 | 215 | 205 | 195 |

| USt37-2 | - | - | - | - | - | - | - |

| RSt37-2 | - | - | 235 | 225 | 215 | 215 | 215 |

| St37-3 | - | - | - | - | - | - | - |

| St52-3 | 510-680 | 490-630 | 365 | 355 | 345 | 335 | 325 |

Scope of Application

ST37 steel plate is especially suitable for heavy-duty parts of welded structures, such as bridges, flood doors, storage tanks, water supply tanks, etc., and must be used in the environment and low temperature.

| China | USA | Germany | Japan | France | U.K. | internationality |

| GB3077 | AlSI | DIN | JIS | NE | BS | ISO |

| 20Mn2 | 1320 1221 | 20Mn5 | SMn21 | 20M5 | 150M19 | - |

| 30Mn2 | 1330 | 30Mn5 | SMn24 | 32M5 | 150M28 | - |

| 35Mn2 | 1335 | 36Mn5 | SMnl | 35M5 | 150M36 | - |

| 40Mn2 | 1340 1341 | - | SMn2 | 40M5 | - | - |

| 45Mn2 | 1345 | 46Mn7 | SMn3 | 45M5 | - | - |

| 50Mn2 | 1052 | 50Mn7 | - | 55M5 | - | - |

| 20MnV | - | 20MnV6 | - | - | - | |

| 30Mn2MoW | - | -- | - | - | - | |

| 27SiMn | - | 27MnSi5 | - | - | - | |

| 35SiMn | - | 37MnSi5 | - | 38MS5 | - | - |

| 42SiMn | - | 38MnSi4 46MnSi4 | - | 38MS5 | - | - |

| 20SiMn2MoV | - | - | - | - | - | - |

| 25SiMn2MoV | - | - | - | - | - | - |

| 37SiMn2MoV | - | - | - | - | - | - |

| 40B | 14B35 | 35B2 | - | - | - | - |

| 45B | 50B46H | 45B2 | - | - | - | - |

| 50B | 14B50 | - | - | - | - | - |

| 4OM∏B | 15B41 | - | - | - | - | - |

| 45MnB | 15B48 50B44 | - | - | - | - | - |

| 20Mn2B | - | - | - | - | - | - |

| 20MnMoB | 80B20 | - | - | - | - | - |

| 15MnVB | - | - | - | - | - | - |

| - | - | - | - | - | - | - |

| - | - | - | - | - | - | - |

| 20MnVB | - | - | - | - | - | - |

| 40MnVB | - | - | - | - | - | - |

| 20MnTiB | - | - | - | - | - | - |

| 25MnTiBRE | - | - | - | - | - | - |

| 2OSiMnVB | - | - | - | - | - | - |

| 15Cr | 5015 5115 | 15Cr3 | SCr21 | 12C3 | 523A14 523M15 | - |

| 15CrA | - | - | - | - | - | - |

| 20Cr | 5120 | 20Cr4 | SCr22 | 18C3 18C4 | 527A19 527M20 | 683/11 20Cr4 20CrS4 |

| 30Cr | 5130 | 28Cr4 | SCr2 | 28C4 32C4 | 530A30 530A32 | - |

| 35Cr | 5135 | 34Cr4 37Cr4 | SCr3 | 38C4 | 530A36 | 683/8 3、 3a、 3b |

| 40Cr | 5140 | 38Cr4 41Cr4 | SCr4 | 42C4 | 530A40 530M40 | 683/1 4、 4a^ 4b |

| 45Cr | 5145 | 42Cr4 | SCR5 | 45C4 | - | - |

| 50Cr | 5150 5152 | - | - | 50C4 | En48 | - |

| 38CrSi | - | - | - | - | - | - |

| 12CrMo | 4119 | 13CrMo44 | - | 12CD4 15CD2 | - | - |

| 15CrMo | ASTM A-387Gr. B | 15CrMo5 16CrMo44 | SCM21 | 15CD4. 05 | BS1653 | - |

| 20CrMo | 4118 | 20CrMo5 22CrMo4 | SCM22 | 18CD4 20CD4 | CDS 12 CDSllO | - |

| 30CrMo | 4130 | 25CrMo4 | SCM2 | 30CD4 | CDS 13 | - |

| 30CrMoA | - | 32CrMol2 3ICRMo12 | - | - | - | - |

| 35CrMo | 4135 4137 | 34CrMo4 35CrMo4 | SCM3 | 35CD4 | 78A37 | 683/1 C35ea C35eb |

| 42CrMo | 4140 4142 | 41CrMo4 42CrMo4 | SCM4 | 40CD4 42CD4 | 708M40 708A42 709M40 | 683/1 3 |

| 12CrMoV | - | - | - | - | - | - |

| 35CrMoV | - | 35CrMoV5 | - | - | - | - |

| 12CrlMoV | - | 13CrMoV4.2 | - | - | - | - |

| 25Cr2MoVA | - | 24CrMoV5.5 | - | - | - | - |

| 25Cr2MolVA | - | - | - | - | - | - |

| 20CR3MoWVA | - | 21CrVMoW12 | - | - | - | - |

| 38CrMoΛl | 6370 (ΛMS) | 34CrAlMo5 41CrAlMo7 | SACM645 | 40CAD6.12 | 905M39 | 683/10 41CrAlMo74 |

| 20CrV | 6120 | 22CrV4 | - | 22CrV4 | - | - |

| 40CrV | 6140 | 42CrV | - | 42CrV4 | - | - |

| 50CrVA | 6150 | 50CrV4 | SUPlO | 50CV4 | 735A50 | - |

| 15CrMn | - | 16MnCr5 | - | 16MC5 | - | - |

| 20CrMn | 5120 | 20MnCr5 | SMC21 | 20MC5 | - | - |

| 40CrMn | 5140 | - | SMC3 | - | - | - |

| 20CrMnSi | - | - | - | - | - | |

| 25CrMnSi | - | - | SMKl | - | - | - |

| 30CrMnSi | - | - | - | - | - | - |

| 30CrMnSiA | - | - | - | - | - | - |

| 35CrMnSiA | - | - | SMK2 | - | - | - |

| 20CrMnMo | 4119 | 20CrMo5 | SCM23 | - | - | - |

| 40CrMnMo | 4140 | - | - | - | - | - |

| 20CrMnTi | - | - | SMK22 | - | - | - |

| 30CrMnTi | - | 30MnCrTi4 | - | - | - | - |

| 20CrNi | 3120 | 20NiCr6 | - | 20NC6 | 637A16 637M17 | - |

| 40CrNi | 3140 | 46NiCr6 | SNCl | 35NC6 | 640A35 640M40 | - |

| 45CrNi | 3145 | 45NiCr6 | - | - | - | - |

| 50CrNi | 3150 | - | - | - | - | - |

| 12CrNi2 | 3115 | 14NiCrlO | SNC21 | IONCll 14NC11 | - | - |

| 12CrNi3 | 3310 | 13NiCrl2 | SNC22 | 10NC12 14NC12 | 655A12 655M13 | - |

| 20CrNi3 | - | 22NiCrl4 | - | 20NC11 | - | - |

| 30CrNi3 | - | 28NiCrlO 31NiCrl4 | SNC2 | 30NC11 30NC12 | - | - |

| 37CrNi3 | - | 35NiCrl8 | SNC3 | 35NC15 | - | - |

| 12Cr2Ni4 | E3310 | 14NiCrl8 | - | 12NC15 | - | - |

| 20Cr2Ni4 | E3316 | 22NiCrl4 | - | 20NC14 | 659A15 659M15 | - |

| 20CrNiMo | 8620 8720 | 20NiCrMo2 21NiCrMo2 | - | 20NCD2 | 805A20 805M20 | - |

| 40CrNiMoA | 4340 9840 | 36NiCrMo4 40NiCrMo6 | SNCM8 | 35NCD5 40NCD3 | 817M40 816M40 | - |

| 45CrNiMoVA | 4437 | - | SNCM9 | - | - | - |

| 18Cr2Ni4WA | ||||||

| 25Cr2Ni4WA |

PACKING AND DELIVERY

Packing and delivery

Our company currently has 12 product series, including low-alloy high-strength steel plates, alloy structural steel plates, more than 300 steel grades, and more than 400 thickness specifications of wide and thick steel plates. Among them, more than 180 varieties are produced in accordance with foreign standards. Our products are exported to more than 100 countries and regions around the world, including Europe, America, and Asia, and have been well received by domestic and foreign customers.

FACTORY APPEARANCE

The factory covers an area of 20,000 square meters and has 8 advanced fully automatic cold forming production lines, 6 hot rolling production lines, more than 20 feeders, 2 environmentally friendly hot-dip galvanizing production lines, and 2 oxygen-free annealing furnaces. It has invested in the construction of galvanized steel, color steel, seamless steel pipes, cold-rolled plates, stainless steel products and other production lines in China, with an annual production capacity of 400,000 tons.

APPLICATION AREAS

Every staff member of our company follows the principles of dedication, professionalism and integrity, focusing on the needs of our customers and making every effort to solve the problems raised by them. We firmly believe that quality is the basis for the survival of an enterprise, and our customer-oriented philosophy runs through every aspect of product design, manufacturing, sales and service.

RELATED PRODUCTS

GET A FREE QUOTE